Performance estimates analysis

Analysis of Performance Estimates for Heat Technologies 2015

In 2015 RECC initiated a long-term project to examine the performance information being given to consumers of heat technologies at the pre-contractual stage.

Our analysis of nearly 50 actual performance estimates has allowed us to shed light on the adequacy of the compulsory technical information given at the pre-contractual stage.

Our findings suggest widespread non-compliance with many installers appearing to regard the MCS performance information standards as optional, and to be confused by the rules.

RECC has made have made a series of recommendations, both overarching and technology-specific.

Publication Date: March 2016

Contents

Executive Summary and Conclusion

- What are standards for?

- What is information for?

- What is the information problem?

- Analysis of Performance Estimates

- Research on Performance

- Executive Summary – Conclusion

- Generic Recommendations

- Heat Pump Recommendations

- Solar Thermal Recommendations

- Biomass Recommendations

Main Report

- Introduction – What is the Problem?

- 1.1 RECC Background

- 1.2 What are standards for?

- 1.3 What is information for?

- 1.4 The Consumer Rights Act

- 1.5 Methodology

- Heat Pumps, Solar Thermal and Biomass – Context, Standards and Analysis

- 2.1 Performance estimate analysis

- 2.2 Heat Pumps

- 2.2.1 Context

- 2.2.2 MCS Obligations

- 2.2.3 Analysis and top-level findings

- 2.2.4 Complaints

- 2.2.5 Heat Pump Case Studies

- 2.3 Solar Thermal

- 2.3.1 Context

- 2.3.2 MCS Obligations

- 2.3.3 Analysis and top-level findings

- 2.3.4 Complaints

- 2.3.5 Solar Thermal Case Studies

- 2.4 Biomass

- 2.4.1 Context

- 2.4.2 MCS Obligations

- 2.4.3 Analysis and top-level findings

- 2.4.4 Complaints

- 2.4.5 Biomass Case Studies

Conclusion and Summary of Recommendations

Executive Summary and Conclusion

I: What are standards for?

Compliance with MCS standards is a demonstration of good industry practice as defined by the relevant MCS Technical Working Groups. MCS standards aim to protect consumers and promote the sector by ensuring that companies:

- perform to a minimum standard of good technical practice;

- conform to safe practice;

- give customers defined technical, performance and operational information about the generator; and,

- give customers pre-contract performance information so they can make technical comparisons and, therefore, informed decisions.

For companies involved in the small-scale renewable energy generation supply chain, MCS standards are 'an agreed way of doing something.' They are designed to help companies improve their performance and reduce risk. They create a level playing field so that rogue companies do not cut corners or mislead consumers, and thereby protect honest companies. MCS standards describe the technical information that should be given to consumers at different stages of the journey, including before the contract is signed, and, where relevant, define the values that should be included. The MCS Certification Bodies are accredited by UKAS to assess installers to MCS Standards and this includes the pre-contractual performance information.

The Renewable Energy Consumer Code (RECC) is backed by the Certified Trading Standards Institute (CTSI) as part of the Consumer Codes Approval Scheme (CCAS). The Code is designed to ensure high standards of service before, during and after a contract with a consumer is agreed. Importantly, these high standards include ensuring that consumers are not subjected to poor marketing and sales practice. The Code requires its members to comply with MCS standards generally and this includes the provision of MCS-compliant performance information specifically.

II: What is information for?

Information is vital to ensure that any competitive market operates efficiently. Fundamental to the performance information issue discussed in this paper is the wider principle of consumer access to information. It is important to highlight this principle for two main reasons.

- Firstly, information provision is a fundamental consumer right. Consumers make better choices when they are well-informed. They are far more likely to be able to make appropriate decisions if they are given the information they need to do so.

- Secondly, consumers are more likely to make a purchase in a market in which they can confidently make comparisons. In short, there is a wealth of research showing that consumer inertia is more likely when consumers do not have adequate knowledge. Serious information asymmetries damage markets and can lead to market failure.

The information a consumer receives before the contract is signed is the most important information of all. Consumers cannot base their purchasing decisions on information provided to them at completion stage.

Consumer Contracts Regulations and Consumer Rights Act

It is worth stressing the issue of risk in relation to standards. Standards should help companies reduce risk by helping them avoid practice that may be unsafe or unlawful for example. It is within this context that consumer protection legislation is relevant.

The critical nature of pre-contractual information is recognised in law in the Consumer Contracts (Information, Cancellation and Additional Charges) Regulations 2013 (the CCRs) and in the Consumer Rights Act 2015. The CCRs state that the trader must give the customer information about the 'main characteristics' of the goods before the contract is agreed. This is reinforced by the Consumer Rights Act 2015 as this confirms that the 'main characteristics' of the goods must form part of the contract between the trader and the customer. Furthermore, if the goods don't comply with the 'main characteristics' as described then the trader will be in breach of the Consumer Rights Act and, therefore, the customer will be able to pursue a relevant statutory remedy.

It is important to note that the Consumer Rights Act 2015 changed the law related to pre-contract information: all verbal and written statements made by a company about the company or its services are now binding if that information influences the consumer's decision when deciding to enter into the contract or when making a decision about the service after entering into the contract. In other words – misleading statements can now be seen in law as contractual terms.

While performance estimates for small-scale renewable generation installations cannot be precise and are not an absolute guarantee of actual performance, they do need to be reasonable, rational and based on realistic assumptions. If they are not, and consumers rely on them, they may be able to seek legal remedy.

III: What is the information problem?

The evidence from RECC's research set out in this report shows that many customers and potential customers are receiving confusing, misleading and potentially damaging information from small-scale renewable energy generation installers. There is evidence this is causing consumer harm.

RECC auditors examine the interface between consumers and installers in detail. More than 200 in-depth audit site-visits were carried out in 2013, a further 170 carried out in 2014 and 160 in 2015. Some auditors have audited more than 100 installers. In relation to performance estimates specifically, these audits reveal a growing dislocation between installer obligations as laid down by the industry through the MCS standards and actual practice for the three heat technologies; heat pumps, biomass and, to a lesser extent, solar thermal. RECC has grown increasingly concerned about the quality and reliability of performance information for these technologies.

Other indicators are consistent with the evidence reported by auditors:

- pre-contractual information given to consumers is the most frequent area of non-compliance found during RECC audits;

- non-compliance usually relates to the quote document and/or the performance estimate;

- more than 70 per cent of installers who are being audited are found to be non-compliant in their approach to pre-contractual information; and,

- there has been a significant increase in the number of complaints about the three heat technologies – there are now significantly more complaints about all three heat technologies than there are about Solar PV (expressed as a percentage of total domestic installations).

Complaints can be complex and involve as much as two months of mediation. Around 1 in every 5 complaints leads to the independent arbitration process.

IV: Analysis of performance estimates

With a view to understanding these issues more clearly, RECC initiated a long-term project to examine the performance information being given to consumers of heat technologies at the pre-contractual stage. This involved:

- a review of the obligations on consumer performance information within the MCS standards MIS 3001, MIS 3004 and MIS 3005;

- the development of three technology-specific compliance tools to help RECC auditors make a consistent appraisal of performance estimates given to consumers by installers;

- an analysis of nearly 50 actual performance estimates given to consumers by installers collected during routine RECC audits and other compliance monitoring activities;

- a review of research evidence available on the actual in-situ performance of the three heat technologies in the UK domestic setting; and,

- the development of specific recommendations to improve the information given to consumers.

Our analysis of nearly 50 actual performance estimates has allowed us to shed light on the adequacy of the compulsory technical information given at the pre-contractual stage. It is important to note that because most companies deploy template documents, each proposal analysed is likely to reflect typical practice for that whole company. In other words, the performance estimates examined represent an analysis of the performance templates used by the companies and therefore reflect the business models deployed by the installers and the broad experience of the customers served by these companies during that period. The most significant top-level results of our analysis are summarised below.

Note on methodology.

The procedure used by RECC to select companies for audits and spot checks is risk-based which means that the companies included in this report are not a random sample of RECC members. However, companies selected for audit tend to be larger and some very large installers are included in the analysis. This means that the research does reflect the experience of a significant proportion of domestic customers.

Heat Pump Performance Estimates – 9 analysed in detail:

- seven out of the nine estimates were not clear or accessible;

- one estimate gave no figure for overall heat demand, while two others gave information contradicted by very different values in alternative estimates with no explanation;

- three out of the four estimates for GSHPs did not give the required technology-specific design information included in MIS 3005 (4.4.24);

- in only three estimates were the main performance values consistent (for example, as described in the methodology set out in Appendix E of MIS 3005);.

- in five estimates the main values were significantly misleading; and,

- all the three estimates that included 'alternative estimates' (based on an alternative methodology) were presented in a non-compliant way and were misleading.

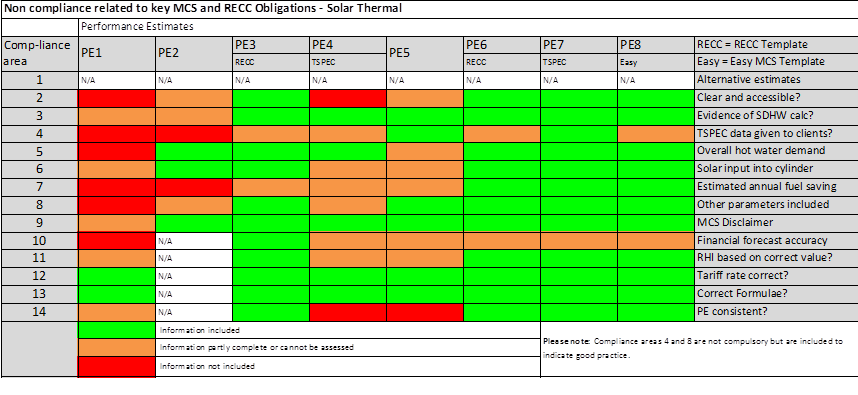

Solar Thermal Performance Estimates – 8 analysed in detail:

- four out of the eight estimates offered reasonably good information but the other four were not clear or accessible;

- one estimate gave no figure for overall hot water demand and another gave confusing information about demand;

- the estimated annual fuel saving is one of only two values that are compulsory yet five installers either failed to include this figure or the information was not adequately clear;

- financial forecasts were not fully compliant in five estimates and were misleading in one other; and,

- the main values were not consistent in two estimates and only partially consistent in one other.

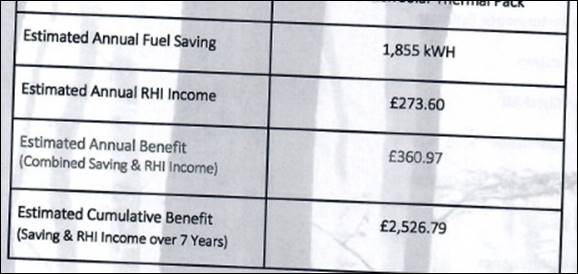

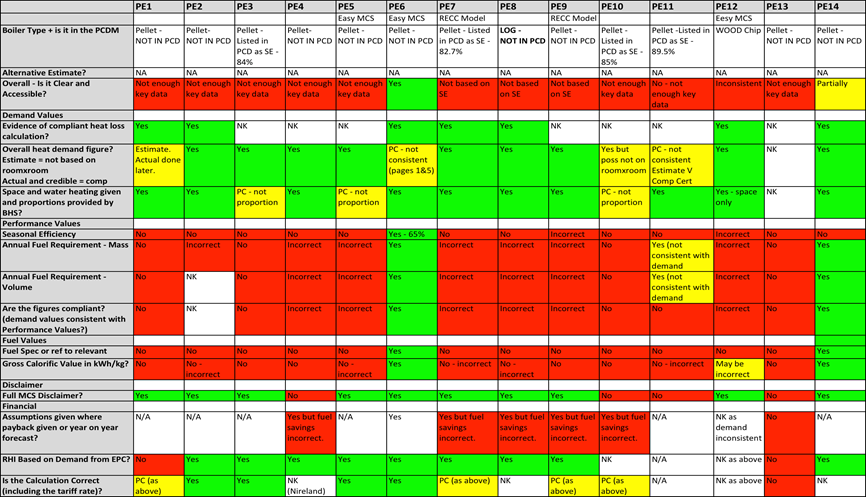

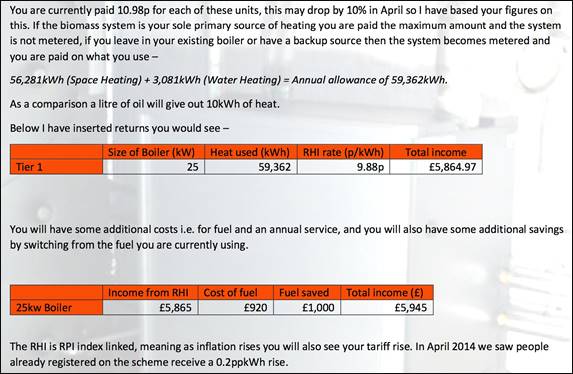

Biomass Performance Estimates – 14 analysed in detail:

- only three of the fourteen estimates gave a seasonal efficiency figure, and, of those, only one estimate included the correct value;

- half the estimates did not state the calorific value of the fuel, and only two estimates gave the MCS value of the fuel in kWh/kg while the value stated for pellets ranged from 4.4kWh/kg to 5.4 with most stating it as 4.8;

- four estimates did not include the MCS disclaimer;

- twelve estimates were not clear or accessible because they did not include the key data required, such as an estimate of fuel mass needed;

- ten estimates did attempt to indicate an estimate of fuel use but seven of those significantly underestimated the fuel needed as detailed in MIS 3004;

- four estimates did not include any of the following values related to performance:

- seasonal efficiency

- mass of fuel required

- volume of fuel required

- performance figures consistent with demand indicated

- fuel specification

- calorific value of fuel in kWh/kg;

- most of the boilers were not in the PCD, and, of the three that were, none used the PCD seasonal efficiency figure.

V: Research on Performance In-Situ

Many of the performance estimates RECC examined as part of this research revealed very poor practice. Yet this would be less damaging if other, third-party empirical evidence demonstrated a good correlation between actual in-situ experience and expected performance of small-scale renewable heat generation systems. The reality is very different however. This paper describes the relevant research (with references) in in Section 2 and the main findings are summarised below.

Heat Pumps

The UCL Energy Institute Analysis of Heat Pumps Installed via the RHPP Scheme – completed in December 2014

This field trial monitored several hundred domestic installations supported by the Renewable Heat Premium Payment (RHPP) grant scheme. The top-level findings show a mean SPF H4 of 2.3 for ASHPs and 2.48 for GSHPs for the Sample C UKSET. Overall, however, the authors place stress on the SPF H2 results and conclude that while more than 90% of installations have resulted in some carbon savings, more than 40% of ASHPs and more than 20% of GSHPs in the study operate below the threshold used by the European Commission to classify as renewable – SPF of 2.5. DECC's recent RHI impact assessment is blunt:

“The latest RHPP evidence concludes that heat pump performance across the whole RHPP stock monitored averages 2.3 (ASHP) and 2.75 (GSHP). It also concludes that only a portion of the total heat pump stock operate at an SPF of 2.5 or greater; 53% (ASHP) and 77% (GSHP).”

This stark contrast between these field trial results and the marketing claims made for heat pumps represents a serious challenge for the industry and its regulators. The underperformance is severe and immediate action should be taken to improve the actual performance of the technology in-situ. A first and critical step is through the provision of better information to enable end users to make informed decisions.

The EST Phase I (completed 2010) and Phase II (completed 2013) Trials –

The Phase I trial revealed that most heat pumps were not performing as well as expected as the median system efficiency for air source heat pumps (ASHP) was found to be just 1.83 with the highest 2.2. The median for ground source heat pumps was 2.31 with the highest over 3.0. The detailed analysis of the field trial led directly to the revised MCS Standard MIS 3005 that came into force in 2012.

Phase 2 of the field trial study was carried out between 2010 and 2013. This Phase II study is widely misunderstood as a 'stand alone' trial involving a new sample of installations. In fact, the phase II 're-set' the Phase I trial with 38 of the original installations selected for a range of interventions in an attempt to improve their performance. Those interventions ranged from major re-sizing to minor modifications. Six new sites were also included and installations carried out in accordance with the new MCS standard. Performance improvements were modest - average SPFs reported were 2.82 for GSHP and 2.45 for ASHPs.

Solar Thermal

Energy Saving Trust field trial 2010 - 2011

One large-scale field trial carried out by the Energy Saving Trust from 2010 to 2011 collected data from 88 domestic installations throughout the UK and Ireland. The median amount of hot water provided by the solar thermal systems as a percentage of hot water used was 39%. The best performing systems provided 60% and the lowest 9%. Typical savings for a well-installed and properly used system were estimated to be £55 per year when replacing gas and £80 per year when replacing electric immersion. EST continues to quote similar savings in its current advice on Solar Thermal.

Installers frequently claim that solar thermal installation can 'typically' provide 60% (or more) of a household's hot water needs. There is little evidence from reliable and impartial research on UK systems to support this claim. A well-designed and installed system may provide 60% of hot water needed but this is the best in-situ performance identified in the relevant field trial.

Biomass

DECC-commissioned desk-based study

There is very little published data on in-situ domestic biomass efficiency in the UK. A recent DECC-commissioned review of evidence identified one study of biomass installations in Wales. The trial, which included domestic installations, was carried out in 2010 and reported disappointing results with very few systems operating as designed. The main problem was found to be boiler over-sizing leading to poor efficiency.

A more recent DECC-commissioned desk-based study of more than 100 (mostly non-domestic) installations reported significant underperformance with average in-situ efficiencies of 66%. That study prompted DECC to commission a large field study of domestic boilers that is due to commence in the first quarter of 2016 and will last for one year.

DECC-commissioned methodology for field trial and analysis of non-domestic RHI data

The study described above led directly to a DECC proposal for a biomass field trial designed to obtain empirical data about domestic biomass boiler efficiency. In 2015 KIWA (in partnership with Amec Foster Wheeler and BRE) published their methodology for such a field trial; this proposal was agreed by DECC and the trial is due to start in April 2016. Preliminary research for the trial and published by KIWA shows that low Utilisation Factors (UFs) are one likely cause of low in-situ efficiencies. The non-domestic RHI data examined for this report shows that boilers are operating below a 15% UF for six months of the year i.e. an average of only 9 minutes in every hour. The authors of the above study consider it probable that low UFs are also likely to be common among domestic installations.

KIWA piloted its proposed field-testing methodology on a domestic boiler by measuring variations in boiler efficiencies under different loads. The study found that the boiler efficiency decreased dramatically as UFs decreased and it concluded that this is a trend it expects to see in boilers of all sizes. Overall, KIWA report that biomass boiler efficiencies fall dramatically when UFs fall below 30%. A UF of 5% corresponds to an efficiency of 25% and a UF of 28% gives an efficiency of just over 70%. The report states:

“These low values are believed to be little known (and certainly not discussed) in the biomass industry.”

The authors of both DECC-commissioned reports comment on widespread confusion among manufacturers, suppliers and installers regarding the difference between:

- 'nominal' or 'manufacturer's specified' efficiency; and,

- in-situ efficiency.

Those conclusions are consistent with the RECC analysis of performance estimates. In fact, DECC now assumes that in-situ performance of domestic biomass boilers will be significantly lower than the efficiencies as stated in the Products Characteristics Database (PCD).

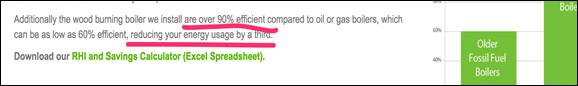

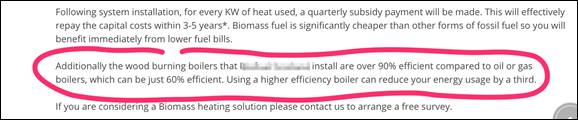

Given the absence of reliable field trial data, the actual evidence available suggests that installers should adopt a cautious approach to forecasting efficiency and, therefore, predicted fuel requirements. The reality, however, is very different. The two DECC-commissioned reports are right to suggest that there is widespread confusion about biomass efficiency for the following reasons (see 2.4.1e below):

- there is a widespread assumption among installers (and among stakeholders generally) that nominal efficiency is shorthand for system or boiler in-situ efficiency;

- companies frequently and wrongly refer to the 'nominal' or 'manufacturer's' efficiency as the likely actual performance that will be achieved;

- boiler combustion efficiencies are sometimes used to calculate consumer fuel requirements; and,

- installers frequently advertise system efficiency levels of over 90% (see section 2.4.1f) and even refer to Seasonal Efficiency rates of over 90% in Compliance Certificates (for boilers not in the PCD).

All of the above issues are compounded by further confusion regarding the energy content of fuel and other important values specified in the MCS standard. It is RECC's view that, as a result of this confusion and poor practice, consumers are being given misleading information and that this is causing significant consumer harm. This harm is obvious from the case study information detailed in Section 2 as fuel requirements are grossly underestimated.

VI: Executive Summary – Conclusion

The evidence reported by RECC auditors and the performance estimate analyses described above (and in Section 2 below) suggest that many installers appear to regard the MCS standards related to performance information as optional. Some may consider the relevant standards to be 'guidelines' and, therefore, not compulsory. Some installers are clearly confused by the rules. Pre-contract performance information does not appear to be the subject of inspections carried out by the Certification Bodies. Installers are frequently surprised when RECC auditors insist that specific values be included in formal pre-contract performance information. Others argue with auditors about the inclusion of figures that are clearly required by the MCS standard.

The contrast between the research evidence on performance and what consumers are actually told is not sustainable. Very good evidence shows that a significant number of renewable heat technology installations are badly designed and are underperforming. This, coupled with a lack of good pre-contract information, will lead to adverse publicity, customer inertia and distrust. An obvious repercussion is the impact this is having on installers that do actually comply with MCS rules – many of those audited by RECC are frustrated by companies that clearly operate outside the MCS standards.

Of equal concern is the belief that the values included in the standards can be adjusted and defined as the installers wish. This is most evident with biomass where there is little or no consistency in values such as the energy value of fuel (per kg) and how boiler 'efficiency' should be defined and presented. Values are clearly manipulated to predict system efficiency as high as possible and fuel requirement as low as possible – even when the figures are clearly incorrect. Heat pump installers often see no problem in supplying two completely contradictory estimates (one based on MCS methodology and another using calculators supplied by manufacturers) with no explanation for differences in results. Other installers simply ignore the MCS requirements completely and, instead, give consumers non-compliant predictions of RHI income.

The evidence shows that, because so many installers deploy non-compliant practice, customers currently cannot approach the formal performance estimate with confidence that the figures are reasonable, rational and based on realistic assumptions. Installer practice must improve in this respect. Better and clearer rules about what customers should be told are an important way to help customers identify good (and bad) practice and have confidence in the systems they are being offered.

VII: Recommendations

This section contains 'generic' recommendations for consideration by MCS Management and sections VIII, IX and X include the sector-specific recommendations for consideration by the MCS Technical Working Groups.

Generic Recommendations

In addition to the technology-specific recommendations below, RECC has a series of generic recommendations applicable to all heat technologies or to the approach taken by MCS on the subject of consumer pre-contract performance information.

- Recommendation 1

MCS initiate a review of the way installer obligations on performance information are being assessed as compliant with MCS Standards. This review should investigate whether the Certification Bodies check for compliance and how compliance is tested. This review should also investigate how often installers are found to be non-compliant and what sanctions are imposed. MCS should assess whether the current arrangement can ensure compliant practice related to performance information in the long term or whether these installer obligations should be monitored using a different mechanism.

- Recommendation 2

MCS revise the standards for all three heat technologies to introduce clearer performance information that is easier for customers to compare at the pre-contractual stage using a compulsory format that includes a compulsory set of performance values. Recommendations for each technology on this issue are included in sections VIII, IX and X.

- Recommendation 3

MCS should consider incorporating permanent expert consumer protection representation on the MCS Technical Working Groups.

- Recommendation 4

MCS and RECC should consider the development of formal consumer guides to the heat technology standards to give customers better information about the performance forecasts they are given. One source of funding for this could be the MCS Charitable Foundation.

VIII: Heat Pump Recommendations

Core Performance Values

MIS 3005 does require installers to provide comprehensive performance information to the customer in the form of the Compliance Certificate – but this is provided after the installation is complete. Industry representatives have questioned the need for the Compliance Certificate and have argued that is should be replaced with a 'voluntary' Commissioning Checklist.

It is RECC's view that robust performance information is vital if consumers are to make an informed decision about a heat pump installation and to help avoid costly disputes. But it is clear that installers are confused about what information should be provided.

- Heat Pumps Recommendation 1

The pre-contract design and performance information given to customers must be improved. This information must be given to customers in a consistent manner using standard terminology. MIS 3005 should be changed to incorporate a compulsory set of defined values that should be presented to the customer in a standard format. To this end, RECC proposes that a revised Appendix E (excluding the section on RHI values) of the current MIS 3005 should be made compulsory for this purpose.

There is widespread confusion within the industry about when the full technical survey can be carried out in relation to the contract agreement. Some installers claim the contract can be agreed based on a rough estimate of performance with the full technical survey taking place later. In fact, the intention of the MCS standard is clear - the technical heat loss assessment must be carried out before the contract is agreed . For this reason, our Recommendation 1 should not impose any additional burdens on installers who currently comply with the standard. Installers must carry out a formal technical survey to draw up a compliant design before contract agreement, therefore all of the information necessary to populate the current Appendix E should be available at the pre-contract stage.

Some industry representatives have recently argued that installers should be free to agree contracts before formal heat loss assessments and, instead, should be allowed to base performance and cost estimates on agreed models or preliminary estimates.

- Heat Pumps Recommendation 2

RECC strongly recommends that MCS resist pressure to allow formal contracts to be agreed before technical survey stage for the following reasons:

- MCS and RECC rules currently allow preliminary estimates (that are not based on full technical surveys) to be given to customers as long they make clear that the formal performance estimate may change after the technical survey. However, the formal quotes and estimates based on full technical surveys must be given to the customer before the contract is agreed.

- Current RECC rules allow installers to charge consumers for full technical surveys prior to contract agreement. These charges must be reasonable.

- The installer must carry out a room-by-room heat loss calculation to make sure that the system will perform with an SPF of at least 2.5 and – after March 2016 – the installer will need the technical survey results to determine the exact SCOP. It is critical consumers are given this information prior to contract agreement.

- Formal contracts agreed prior to full technical survey stage are not consistent with the principles of consumer protection and access to information.

- If installers are allowed to agree contracts before the full technical survey is carried out then RECC would predict an increase in disputes for several reasons:

- rough estimates are more likely to be incorrect (they may wrongly show the SPF to be above 2.5 for example);

- contract agreements before formal site surveys are more likely to be used as a sales tactic by companies that sell in the home; and,

- pressure selling is much more likely where the formal MCS-compliant technical survey is not available.

- Allowing contract agreement before the formal performance estimate is available will not give consumers the information they need to help them avoid poorly designed and inefficient installations.

Design Information

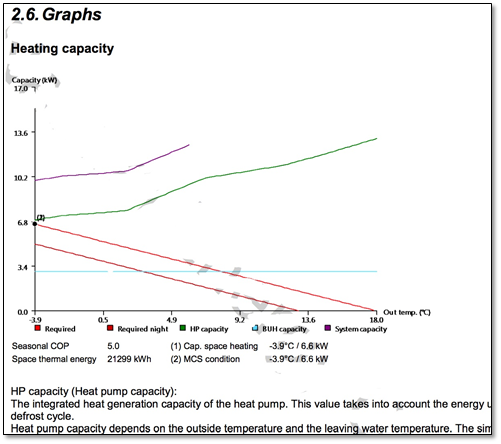

From March 2016 all installers have had to comply with the Energy Related Products Directive and will obtain the SCOP data from spreadsheets available from MCS. Some installers have argued that this move to heat pump SCOP information places too much emphasis on the efficiency of heat pump and this risks giving the wrong signal to customers about system use and efficiency.

It is RECC's view that the new requirements under the Directive do not carry this risk as long as the heat loss and emitter design information is provided to customers in a compliant manner before the contract is signed. As detailed below (2.2.2 - MCS Obligations) MIS 3005 already states that – before contract agreement – all customers must be given: specific room heat losses; emitter choice and sizes; and information about the Heat Emitter Guide. Our evidence shows that this information is often excluded from performance estimates or is not provided in an adequate, clear and accessible manner. Only one performance estimate discussed in Section 2.2.3 below included the information about heat losses and emitters in a compliant way. Five omitted this information entirely.

- Heat Pumps Recommendation 3

The design information on heat losses and emitters should be defined more clearly and given to customers before contract agreement using standard terminology and in a standard compulsory format.

Again, this recommendation does not impose extra obligations on installers. Instead, it will require installers to fulfil an existing obligation in a different way.

Design and performance information - timingAs described below (2.2.2 – MCS obligations) the MIS standard is not totally clear about when the performance and design information should be given to customers.

- Heat Pumps Recommendation 4

The standard should explicitly state that the design and performance information should be provided before the contract is signed. All references to 'at or before' contract agreement should be deleted from the standard. These changes should include all of the obligations related to information provided that relates to:

- Alternative estimates

- Overall design and demand

- Hot water demand

- Specific room heat loss information and emitter selection

- Design for Ground Source Heat Pumps

- System Performance

- Running costs

Alternative Estimates

As with MIS 3001(Solar Thermal) and MIS 3004 (Biomass), MIS 3005 (heat pumps) includes a general requirement that any estimate using an alternative methodology must clearly describe and justify the approach. Furthermore, any alternative estimate must not be given greater prominence than the MCS estimate and, where the results vary significantly from the MCS estimate, it must be accompanied with a warning that it be treated with caution.

RECC's analysis of estimates shows that the provision of 'alternative estimates' is a key source of confusion. These estimates using alternative methodologies are frequently given more prominence and the results often directly and significantly contradict the formal MCS values (see Section 2.2.5 – Case Studies). This problem is further compounded by the fact that the MCS estimate carries the MCS disclaimer but there is no obligation on the installer to include a similar disclaimer on the alternative estimate. The customer is therefore given the erroneous impression that the MCS estimate is given 'as guidance only' and may be incorrect – while the other estimate is therefore more reliable.

The provision of standard design and performance information in a standard format should go some way to mitigate problems associated with alternative estimates. It is RECC's view however that MCS should introduce new rules to prevent further confusion.

- Heat Pumps Recommendation 5

All alternative estimates must include a prominent disclaimer stating that alternative estimates using non-MCS methodology should be treated with caution. Furthermore, the disclaimer should state that it is the MCS performance estimate that should be used when making income and cost assessments and that the alternative estimate has not necessarily used a methodology approved by MCS.

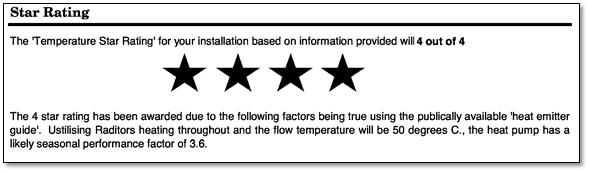

IX: Solar Thermal Recommendations

Core Performance Values

As discussed in section 2.3.2, MIS 3001 currently requires installers to provide only two performance values before contract agreement.

It is RECC's view that robust performance information is vital if consumers are to make an informed decision about a solar thermal installation and to help avoid costly disputes. RECC will need to carry out more analysis to determine why the level of formal complaints about solar thermal installation is the highest out of all the heat technologies. Given that formal complaints represent the 'tip of the iceberg' (as detailed above), the fact that nearly 5% of all installations result in a formal complaint to RECC is not sustainable.

There is some confusion among installers about what information should be provided. This confusion is probably leading to some inaccuracies in some estimates. Overall, however, installer practice related to solar thermal pre-contract information appears to be better than practice evident for the other two heat technologies. Even so, comparisons with the estimates for heat pumps and biomass is not a high bar; half of the Solar Thermal estimates we examined did not offer information that could be properly used by the customer to make an informed choice.

- Solar Thermal Recommendation 1

The pre-contract design and performance information given to customers must be improved. This information must be given to customers in a consistent manner using standard terminology. MIS 3001 should be changed to incorporate a compulsory set of defined values that should be presented to the customer in a standard format before the contract is signed. To this end, RECC proposes that the full TSPEC calculation should be made compulsory for this purpose.

There is widespread confusion within the industry about when the full technical survey can be carried out in relation to the contract agreement. Some installers seem to think the contract can be agreed based on a rough estimate of performance with the full technical survey taking place later. In fact, MIS 3001 is unequivocal on this issue and clearly states that the technical calculation must be carried out before the contract is agreed . For this reason, our recommendation (as above) should not impose any additional burdens on installers who currently comply with the standard. Installers must carry out a formal technical calculation to draw up a compliant design and proposal before contract agreement, therefore all of the information necessary to populate the TSPEC (MCS 024) should be available at the pre-contract stage.

X: Biomass Recommendations

Seasonal Efficiency and Manufacturer's Specified Efficiency

Our analysis of performance estimates (and supported by anecdotal evidence from auditors) has found that a significant proportion of installers do not refer to the Seasonal Efficiency of the boiler in their performance estimates and do not use the SE figure in their performance calculations. Instead, many installers refer to the Manufacturer's Specified Efficiency.

The 'manufacturer's specified efficiency' is often referred to as:

- 'nominal efficiency' (as it is termed in the Compliance Certificate); or,

- 'boiler combustion efficiency'.

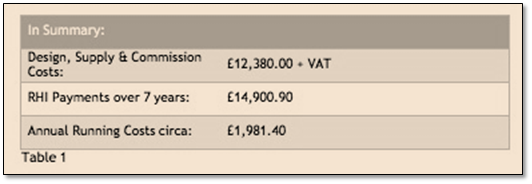

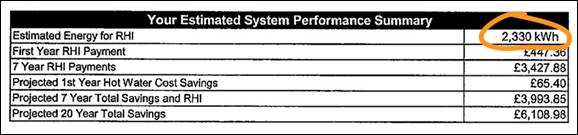

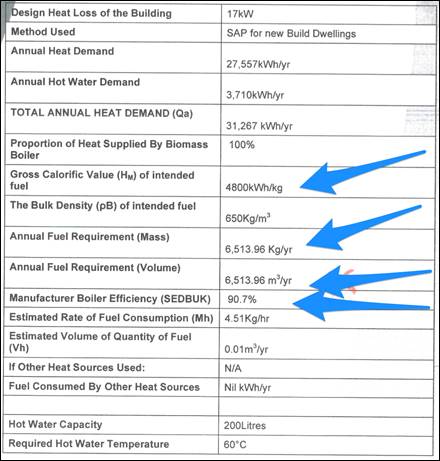

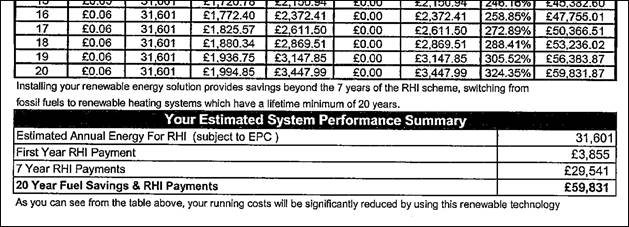

There is no question that installers using 'nominal' or 'manufacturers' specified efficiency' values in performance calculations to estimate fuel levels required are either knowingly or unknowingly exaggerating potential performance. Our analysis found that these practices mean consumers are being given very misleading advice – this is summarised in Table 1 below.

Table 1: Key examples of misleading advice found in analysis of performance estimates.

| Value given in performance estimate by installer | Correct value as calculated by RECC according to MIS 3004 |

|---|---|

| 14460kg/yr fuel required | 22764kg/yr |

| 6500kg/yr fuel required | 11000kg/yr |

| £920/yr cost of fuel required | £2500/yr |

| £1137/yr cost of fuel required | >£2000/yr |

The authors of the DECC commissioned report Review of Biomass Performance Standards, 2014 report that some installers give customers confusing and misleading information about efficiency. They note that the MCS standard MIS 3004 "stipulates that biomass boilers are CE marked and achieve a certain level of boiler combustion efficiency, and EN303:5 2012 (the EU standard for testing solid fuel heating boilers up to 500kW) also makes reference to the boiler combustion efficiency of biomass boilers. These standards are often taken as the system efficiency, whereas the boiler combustion efficiency is only one part of the overall system efficiency of a biomass installation."

They added: "some installers appear to be overstating the likely performance standards of Systems (at 85% and higher) by presenting boiler combustion efficiency as part of the sales process."

Performance calculations should be based on in-situ efficiencies. In essence, from the customer's perspective, references to 'nominal efficiency', the Manufacturer's Specified Efficiency or the boiler combustion efficiency are not useful as they cannot be used to predict fuel requirement.

Section 4.4.1(i) of MIS3004 states that the seasonal efficiency of the boiler should be obtained from the Products Characteristics Database (PCD) or the default value from Table 4a of SAP – currently 65% (or 60% if the boiler is located outside the dwelling). Despite this clarity, there appears to be confusion about what is intended by paragraph 4.4.1(i) and many installers either ignore the obligation deliberately or are confused by it.

-

Biomass Recommendation 1

MCS take immediate action to prevent installers from using boiler nominal (or the Manufacturer's Specified Efficiency) to predict fuel quantities required in MCS Performance Estimates. MIS 3004 should state explicitly that the nominal efficiency figure (or the Manufacturer's Specified Efficiency figure) should not be used in the performance calculation and that any calculations based on those values to predict fuel use will invalidate the performance estimate.

- Biomass Recommendation 2

The MCS Biomass Working Group should initiate a review to decide on the best way to ensure that realistic efficiency levels are used in performance estimates. DECC assumes that actual in-situ efficiencies achieved are significantly lower than those stated in the PCD. MCS should adopt a cautious approach to efficiency at least until results from the 2016 field trial are known.

-

Biomass Recommendation 3

MIS 3004 should include a requirement that a standard template of values (see template proposal below) should be given to customers pre-contract and this template should include a prediction of fuel use that is based on one of the following values only:

- the default SAP figure as identified in MIS 3004 4.4.1(i)

- some other reasonable estimate of in-situ efficiency to be identified by the MCS Working Group (as Recommendation 2 above).

-

Biomass Recommendation 4

If the Seasonal Efficiency values from the PCD are to be used in formal MCS performance estimates then the MCS disclaimer should be adjusted to state explicitly that the estimate of efficiency is not included to indicate a 'minimum'. The disclaimer should explain that the in-situ boiler performance might result in an efficiency that is significantly lower.

2.4.5(b) – The energy content of fuel

There is no one standard value for the calorific energy content of biomass fuel. The MCS biomass calculator, however, includes the following default values:

- 4.4kWh/kg pellets

- 3.8kWh/kg logs

The problem here is obvious – some installers manipulate this value to make system proposals appear more efficient. In the estimates we examined the value stated for pellets ranged from 4.4kWh/kg to 5.4. Most stated the value as 4.8. There is clear confusion among installers about what the standard says about energy content of fuel. While some installers believe the MCS calculator values are compulsory, others think they have every freedom to give values that they choose. There is no level playing field - which gives installers an incentive to exaggerate the energy content of the intended fuel.

- Biomass Recommendation 5

MIS 3004 should contain explicit obligations on energy values for intended biomass fuels. Installers should be required to refer to specific values when calculating performance estimates and those values should be included in a template of pre-contract information. The standard should state that the performance estimate will be invalid if the installer does not refer to the correct energy values for fuel.

2.4.5(c) – Information Template

Our analysis of performance estimates shows that while the majority of installers appear to give customers reasonable information about energy demand, most give very poor or vague information about performance. It is clear that installers are confused about what information should be provided. The performance information we have examined reveals that pre-contract information can be: misleading; inconsistent and therefore confusing; and, can lack important values.

-

Biomass Recommendation 6

The pre-contract design and performance information should be given to customers in a consistent manner using standard terminology. MIS 3004 should be changed to incorporate a compulsory grid of defined values that should be presented to the customer before contract agreement in a compulsory format. To this end, RECC proposes that a revised Appendix C (excluding the section on RHI values) of the current MIS 3004 should be made compulsory for this purpose with two changes:

- Firstly, this standard template should include a specified value for the Energy Content of the Specified Fuel specified in kWh/kg and the MCS Working Group should specify compulsory default values.

- Secondly, the section on 'estimated running costs' should be included as compulsory.

As with Heat Pumps, there is some confusion within the biomass installation sector about when the full technical survey can be carried out in relation to the contract agreement. Some installers seem to think the contract can be agreed based on a rough estimate of performance with the full technical survey taking place later. In fact, MIS 3004 is completely clear on this issue as it states that the technical heat loss assessment must be carried out before the contract is agreed . For this reason, the Biomass Recommendation 5 should not impose any additional burdens on installers who are currently in compliance with the standard. Installers must carry out a formal technical survey to draw up a compliant design before contract agreement, therefore all of the information necessary to populate the current Appendix C should be available at the pre-contract stage.

As with heat pumps discussed above, RECC recommends that MCS resist pressure to allow formal performance estimates to be provided after contracts are agreed.

1. Introduction – What is the Problem?

1.1 Background

“I haven't seen one heat pump performance estimate that is compliant.”

RECC auditors regularly examine the interface between consumers and installers in detail. More than 200 in-depth audit site-visits were carried out in 2013 and a further 170 carried out in 2014 and 160 in 2015. Some auditors have audited more than 100 installers. In relation to performance estimates specifically, these audits reveal a growing dislocation between installer obligations as laid down by the industry through the MCS and actual practice for the three heat technologies; heat pumps, biomass and, to a lesser extent, solar thermal.

Anecdotal evidence from auditors about installer practice related to pre-contractual performance information has included:

- confusion among many installers about what information should be given to customers;

- high levels of non-compliance with obligations related to performance;

- difficulty in assessing member compliance due to complex and non-standard ways of presenting performance information;

- extreme examples of non-compliance;

- examples of 'confusion marketing'; and,

- very few examples of good practice.

Other indicators reflect anecdotal evidence reported by auditors:

- pre-contractual information given to consumers is the most frequent area of non-compliance found during RECC audits;

- non-compliance usually relates to the quote document and/or the performance estimate;

- more than 70 per cent of installers are found to be non-compliant in their approach to pre-contractual information;

- there has been a significant increase in the number of complaints about the three heat technologies – there are now significantly more complaints about all three heat technologies than there are about Solar PV (expressed as a percentage of total installs). See Table 2 below.

Table 2: Formal complaints received by RECC as a % of installations (not including those registered with certification bodies unless joint). Solar PV indicated for reference. These figures exclude:

- all technical complaints sent only to the certification bodies;

- all complaints directed only to the installers; and,

- all complaints where the customer has sought a legal solution without first involving RECC.

| Complaints 2013 | Complaints 2014 | Complaints 2015 (first full year of RHI) | 2015 Complaints as a % of total installs | |

|---|---|---|---|---|

| Heat Pumps: ASHP only GSHP only |

80 64 16 |

120 103 13 |

135 107 28 |

2.68 3.13 |

| Solar Thermal | 37 | 40 | 48 | 4.81 |

| Biomass | 45 | 61 | 160 | 3.86 |

| Solar PV | 937 | 754 | 0.8 |

To help members address practice related to estimates, RECC continues to provide model documents including quotations and pre-contractual information for each technology. These include model performance estimates that are available to members free of charge and have been developed in order to comply with the requirements of the Code, MCS standards and relevant consumer protection legislation. There is also in-depth detailed guidance on the presentation of this information.

1.2 What are Standards For?

Compliance with MCS standards is a demonstration of compliance to good industry practice as defined by the relevant MCS Technical Working Groups. The MCS standards describe what technical information should be given at the pre-contract stage and, where relevant, define the values that should be included. The Certification Bodies are accredited by UKAS to assess installers to MCS Standards.

The Renewable Energy Consumer Code (RECC) is backed by the Certified Trading Standards Institute (CTSI) as part of the Consumer Codes Approval Scheme (CCAS). The Code is designed to help consumers get advice on generation solutions without being subjected to negative marketing/sales tactics, and to ensure high standards of service before, during and after a contract with a consumer is agreed. Importantly, these high standards include ensuring that consumers are not subjected to negative marketing/sales tactics. The Code requires its members to operate compliantly with the MCS standards generally and to provide consumers with MCS compliant pre-contract performance information specifically.

Generally, standards are 'an agreed way of doing something.' They can perform many functions but fundamentally they help disseminate good practice and therefore help companies improve their performance and reduce risk. MCS standards describe the technical information that should be given to consumers at different stages of the journey, including before the contract is signed, and, where relevant, define the values that should be included. The MCS Certification Bodies are accredited by UKAS to assess installers to MCS Standards.

Within the context of the domestic microgeneration sector the MCS standards protect consumers by ensuring companies:

- perform to a minimum standard of good technical practice;

- conform to safe practice;

- give customers defined technical, performance and operational information about the generator; and,

- give customers pre-contract performance information so they can make technical comparisons and, therefore, informed decisions.

While the standards appear to offer concise and clear guidance on the technical practice expected, our research shows that the way the standards define the pre-contractual information that should be given to customers is not always clear.

Our examination of the obligations related to pre-contractual performance information and actual practice shows that there is considerable confusion among installers about their obligations. The rules are often ignored and consumers given pre-contractual information that cannot be used to make properly informed decisions.

1.3 What is information for?

Information is vital to ensure that any competitive market operates efficiently. Fundamental to the performance information question discussed in this paper is the wider principle of consumer access to information. RECC believes it is important to highlight this issue for two main reasons.

- Firstly, information provision is a fundamental consumer right. Consumers make better choices when they are well-informed. They are far more likely to be able to make appropriate decisions if they have the information they need to do so.

- Secondly, consumers are more likely to make a purchase in a market in which they can confidently make comparisons. In short, there is a wealth of research showing that there is more likely to be consumer inertia when customers do not have adequate knowledge.

A microgeneration installation is an example of a complex one-off, long-term purchase when the customer depends on:

- market intervention to ensure good technical standards and good practice; and,

- the expertise and good judgement of the installer.

All markets function best when consumers can exercise choice effectively. Other examples of complex purchases where there is access to regulated information includes the financial sector and the motor industry. Those markets are not perfect, but the consumer's right to vital and comparative information is recognised as beneficial and protected.

The importance of good consumer access to information in the energy sector is widely recognised. Last year Ofgem commissioned a report on the changing information landscape that is enabling consumers to access information about energy tariffs. That report was generally positive about how consumers can access new tariff comparisons but it warned about information asymmetries:

“There are many circumstances where one party can use superior knowledge/expertise to gain advantage by causing confusion blinding the other party with science. In addition, many consumers are very aware these information asymmetries exist. This can fuel a generalised sense of distrust and undermine consumers' confidence that they can tackle an issue effectively. This helps create inertia.”

The same arguments can be deployed within the microgeneration sector. Serious information asymmetries damage markets and can lead to market failure. It is RECC's view that there is a real danger that the markets for heat pumps and biomass are being damaged because of confusion and information asymmetries – the information many people are being given is not reliable or reasonable.

1.4 The Consumer Rights Act

It is worth stressing the issue of risk in relation to standards. Standards should help companies reduce risk by helping them avoid practice that may be unsafe or unlawful for example. It is within this context that the Consumer Rights Act is relevant.

The information a customer receives before the contract is signed is the most important information made available. Consumers cannot base their purchasing decisions on information provided to them at completion stage.

The critical nature of pre-contractual information is recognised in law in the Consumer Contracts (Information, Cancellation and Additional Charges) Regulations 2013 (the CCRs) and in the Consumer Rights Act 2015. The CCRs state that the trader must give the customer information about the 'main characteristics' of the goods before the contract is agreed. This is reinforced by the Consumer Rights Act 2015 that states that the 'main characteristics' of the goods must form part of the contract between the trader and the customer. Furthermore, if the goods don't comply with the 'main characteristics' as described then the trader will be in breach of the Consumer Rights Act and, therefore, the customer will be able to pursue a relevant statutory remedy.

The new Act that came into power in October 2015 not only consolidates and updates existing laws, it also implements new consumer rights. Two rights within the Act are worth highlighting within the context of a discussion about performance estimates.

Firstly – consumers have three 'implied terms' under the Act and one of those core rights is that goods must be 'as described' by the trader. The goods must be what the customer expects.

Secondly – and perhaps more importantly – the Act includes a significant new consumer protection: verbal or written statements, made by the company, about the company or the company's services will be binding if that information influences the customer's decision to enter into the contract.

This new provision is very important because misleading statements are now contractual terms and consumers now have the right to raise a breach of contract against a trader. Prior to this new provision, customers had to raise an 'action of misrepresentation'. Experts consider breaches of contract as easier to prove than actions of misrepresentation. Customers may now be able to claim a breach of contract if they are given misleading or inaccurate performance information.

While performance estimates for small-scale renewable generation installations cannot be precise and are not an absolute guarantee of actual performance, they do need to be reasonable, rational and based on realistic assumptions. If they are not, and consumers rely on them, they may be able to seek legal remedy.

In reality, companies will need to be very careful about all of the pre-contractual and point-of-sale information given to customers – this includes flyers, performance estimates and all verbal information given by sales agents and other company representatives. The standards attempt to define how performance estimates should be deployed but our research shows that not only are a significant proportion of performance estimates non-compliant, some are extremely misleading.

1.5 Methodology

Our research is described in Section 2.

Section 2 describes our examination of a sample of formal performance estimates for each technology. This section also includes: a summary of this analysis; the top-level findings; and, relevant information about complaints made about specific technologies. Section 2 also describes specific case studies to illustrate why specific performance estimates were found to be non-compliant.

Note on methodology.

Nearly 50 formal performance estimates were examined for this report and over 30 selected for analysis and included in the tables below. Most were obtained at formal audit or from spot checks carried out by RECC auditors. The procedure used by RECC to select companies for audits and spot checks is risk-based which means that the companies included in this report are not a random sample of RECC members. However, companies selected for audit tend to be larger and some very big installers are included in the analysis. This means that the research does reflect the experience of a significant proportion of domestic customers.

Furthermore, it is important to note that each proposal analysed is likely to reflect typical practice for that whole company. In other words – the performance estimates examined represent an analysis of the performance templates used by the companies and their approach to the performance calculations. The performance estimates described in this report therefore reflect the business models deployed by the installers and the broad experience of the customers during that period.

2. Heat Pumps, Solar Thermal and Biomass – Context, Standards and Analysis

2.1 Performance estimate analysis

To better understand the problems identified by RECC auditors, RECC developed compliance tools for the three heat technologies. The tools include all RECC and MCS installer obligations to provide pre-contractual performance information and how that information should be presented. The tools were then used to assess compliance by analysing a sample of actual performance estimates for each technology. The results are described below using the following content headings for each technology:- Context – describes relevant research or reports on relevant performance issues.

- MCS Obligations – includes a description of the significant requirements related to pre-contractual performance information in the three technology standards – MIS 3001 (Solar Thermal), MIS 3004 (Biomass) and MIS 3005 (Heat Pumps).

- Our analysis and top-level findings – includes more information about our methodology, a table detailing the results for each technology and a description of the main findings.

- Complaints – describes information from the RECC complaints team relevant to each technology. This also includes relevant case studies.

- Case studies – The case studies illustrate how the assessments were made in the performance estimate analysis described. They also illustrate the consumer impact of poor practice.

2.2 Heat Pumps

2.2.1 – Context

Several studies based on empirical research have examined the performance of heat pumps in UK domestic settings. This is in contrast with the published research on biomass that is almost exclusively restricted to small studies, desk-based research and efficiency modelling (those reports are described in section 2.4.1).

The UCL Energy Institute Analysis of Heat Pumps Installed via the RHPP Scheme – February 2016

This field trial monitored several hundred domestic installations supported by the Renewable Heat Premium Payment (RHPP) grant scheme. The monitoring concluded in December 2014 when the data was handed to the research consortium for analysis and the eventual sample used for the research included slightly fewer than 500 installations. As with the two field trials described above, the main outcome measures examined were the Seasonal Performance Factors (SPFs) at various system boundaries (including H2 and H4), under standard UK weather conditions.

The results are extremely disappointing because they do not demonstrate improved performance compared to the EST and DECC Phase II study cited below . The authors state that these new results are actually consistent with the DECC Phase II findings. Performance efficiency was also found to be lower than a smaller scale preliminary study of RHPP monitored heat pumps that was based on data from just one month (published in 2014).

The study sample was split into several sets for analysis and one of those (Sample C: UKSet) examined performance adjusted to a set of standard external weather conditions chosen to match temperatures used in the Standard Assessment Procedure (SAP) as closely as possible. The analysis of this set found only 55% of ASHPs and 79% of GSHPs met the SPFH2 ≥ 2.5 criterion defined in the EU Renewable Energy Directive. Commenting on this specific finding the authors state: 'the results here indicate that a large proportion (between a third and just under a half) of ASHPs and just over 20% of GSHPs were not operating with sufficient efficiency to be classified as renewable sources of energy.'

The authors describe certain caveats related to the methodology and these include a discussion regarding the extent to which the RHPP sample is representative of the UK domestic market for heat pumps. They also state that there may be an overestimation of heat pump output (and therefore SPF) due to the presence of antifreeze in some primary heat distribution circuits. These and other caveats are described in the report – page 20.

Despite those limitations the authors conclude that the top-level finding show a mean SPF H4 of 2.3 for ASHPs and 2.48 for GSHPs for the Sample C UKSET . Overall, however, the authors place stress on the SPF H2 results and conclude that while more than 90% of installations have resulted in some carbon savings, more than 40% of ASHPs and more than 20% of GSHPs in the study operate below the threshold used by the European Commission to classify as renewable.

DECC has recently made several comments about research on in-situ performance.

DECC's recent RHI impact assessment states:

“The latest RHPP evidence concludes that heat pump performance across the whole RHPP stock monitored averages 2.3 (ASHP) and 2.75 (GSHP). It also concludes that only a portion of the total heat pump stock operate at an SPF of 2.5 or greater; 53% (ASHP) and 77% (GSHP).”

These results should be of serious concern to the industry, DECC and MCS. Since its launch, the RHI is not eligible for installations predicted to achieve a SPF of less than 2.5. These results clearly indicate that a significant proportion of domestic customers (possibly just under one half of those with ASHPs) are now using systems with an actual efficiency that:

- does not classify as renewable under EU law; and,

- would not qualify for the RHI had the performance forecast been more reliable.

The Energy Saving Trust (EST) has published two study reports on heat pump performance:

-

The EST Phase I Trial

The first field trial was completed in 2010 and the results revealed that most heat pumps were not performing as well as expected as the median system efficiency for air source heat pumps (ASHP) was found to be just 1.83 with the highest 2.2. The median for ground source heat pumps was 2.31 with the highest over 3.0. The system efficiency figures were lower than those monitored in similar field trials held in other European countries. The detailed analysis of the field trial led directly to the revised MCS Standard MIS 3005 that came into force in 2012.

-

The EST and DECC Phase II Trial

Phase II of the study was carried out between 2010 and 2013. This Phase II trial is widely misunderstood as a 'stand alone' trial involving a new sample of installations. In fact, phase II 're-set' the phase I trial with 38 of the original installations selected for a range of interventions: from major re-sizing to minor modifications. Six new sites were also included and installations carried out in accordance with the new MCS standard.

-

The EU Renewable Energy Sources Directive requires heat pumps perform to a minimum Seasonal Performance Factor (SPF) (H2) of 2.5 to be classified as renewable. When assessed using that SPF (H2) measure - 20 out of 21 GSHPs in Phase II met or exceeded that criterion. The equivalent figure for ASHPs was 9 out of 15. Five out of the six newly installed heat pumps met the criterion. However, both DECC and the EST consider SPF (H4) to be the most useful measure of performance for householders because it takes into account all of the electricity used by the heating system. According to that assessment the average performance was 2.82 for GSHPs and just 2.45 for ASHPs. Eleven out of 15 ASHPs achieved an SPF (H4) of less than 2.5. Industry representatives have criticised the methodology used in this Phase II study.

-

The EST concluded that performance 'has the potential to improve as the UK market continues to evolve and adopt more rigorous installer standards' and that, as the installations were not fully installed under the MCS standards put in place in 2012, then it expected better technical performance and customer satisfaction in the future. RECC welcomed the introduction of the revised MIS 3005 standard in 2012. That standard (and later revisions) includes installer obligations related to the performance information that must be given to customers and those obligations are described below in 2.2.2.

The DECC Policy Framework

According to DECC, heat pumps will continue to have an important role to play in contributing to fuel poverty milestones and in reducing the carbon associated with domestic heat technologies – as long they operate efficiently and as expected. DECC is proposing to maintain subsidy income available for heat pumps but is also aiming to identify new ways to incentivise better in-situ performance. Commenting on current evidence for in-situ performance DECC states that 'there is increasing evidence that design performance of heat pumps is not well correlated with their in-situ performance' and that some heat pumps are 'unlikely to be providing significant bill savings to the user and are providing less renewable heat than expected.' As a result, DECC is considering removing the link between design performance and payments and wants to ensure better value for money by incentivising better in-situ performance. They propose to do this by offering a 'base' tariff using a default SPF with 'higher payments available to those that can demonstrate better performance.'

2.2.2 – MCS obligations

MIS 3005 contains detailed installer obligations on the provision of pre-contract performance information. Those obligations cover both the design and the performance of the system and fall under the following headings:

- Alternative estimates

- Overall design and demand

- Hot water demand

- Specific room heat loss information and emitter selection

- Design for Ground Source Heat Pumps

- System Performance

- Running costs

A possible source of confusion among installers is that the relevant paragraphs that describe the information that they are expected to give consumers are distributed throughout sections 4.2.1 to 4.3.4 of MIS 3005. For example requirements related to information about demand are contained in paragraphs 4.2.1, 4.3.2(a), 4.2.2 and 4.2.10 – all of these relate to total demand and the possible need for compulsory metering.

A further source of confusion is that the standard is not always explicit about when the information should be provided. Some of the paragraphs in Section 4 of the standard state that the information cited must be 'communicated in writing' to the customer 'at or before the point at which the contract is awarded'. Information provided at the same time the contract is signed is not useful and this is recognised in law. The Consumer Contracts Regulations 2013 clearly states that where consumers do not have adequate 'time to reflect' then the agreement is defined as an 'off-premises contract' - which means that the contract is subject to special consumer rights of cancellation. The term 'at or before' is not precise and does not adequately convey the MCS intention that customers should have 'time to reflect' on the information provided before they are asked to sign the contract.

Other paragraphs are even less clear. For example, the standard does explicitly state that information on the heat pump running costs should be communicated in writing to the client, but it is not clear in paragraph 4.2.8 precisely when this information should be provided. This paragraphs states that the estimate of the annual running cost of the heat pump is contained within the estimate of annual energy performance, but this is not explicit in section 4.3. While 4.3.2 does describe an obligation to give the customer an estimate of the energy needed to run the pump – there is no mention (in 4.3.2) of a need to tell the customer the cost of the energy. There is a lack of precision in the standard about exactly what information should be provided pre-contract. We have summarized the obligations related to performance information in Table 3 below.

Table 3: Performance Information Obligations in MIS 3005

| Obligation | MIS 3005 Paragraph | When should this information be given | Comments |

|---|---|---|---|

| Rules on alternative estimates | 4.3.4 | Applies to pre-contractual information | This warning should be clarified to state that all estimates not based on MCS methodology should be treated with caution. |

| Overall design and demand and information on supplementary heating | 4.2.1, 4.2.2 | Unclear | The information requirements in these paragraphs should be clarified. |

| Hot water demand | 4.2.3 | Unclear | Installer obligation to discuss predicted hot water demand should be clarified. |

| Heat Losses and Emitter Design | 4.2.12-17 | 'At or before' contract agreed | This information is vital as it demonstrates that system efficiency depends on emitter choice. Requirements here should be clarified and standardized. |

| Ground Source Design | 4.2.24 | Unclear | Standard should define when this information should be provided. |

| System Performance | 4.3 | 'At or before' contract agreed | The standard should be explicit about what values must be provided pre-contract. |

| Running Costs | 4.2.8 | Unclear | Standard should define when this information should be provided. |

Installers are confused about what information they must give to customers and when that information should be given and this confusion extends to the core System Performance requirement described in section 4.3 of MIS 3005. This paragraph states:

“An estimate of the annual energy performance shall be calculated or obtained and shall be communicated in writing to the client at or before the point at which the contract is agreed.”

The problem is that paragraphs 4.3.2(a)-(g) describe the calculation – they do not describe what performance information should be given to the customer. As the case studies in Section 2.2.5 indicate – heat pump installers interpret these paragraphs in a variety of ways and, as a consequence, the information given to customers is often vague or misleading or both. No single value can correctly encapsulate heat pump performance. Instead, customers may need all of the information contained in Appendix E of MIS 3005 before they can make a good assessment of the proposal (see section VIII – Recommendations - of the Executive Summary for more on this).

2.2.3 – Our analysis and top-level findings

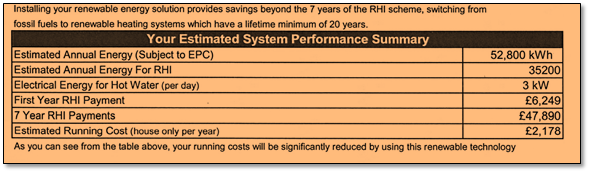

We examined nearly 20 estimates for heat pumps and included 9 in the analysis. This pre-contractual information was measured using the RECC heat pump performance information compliance tool as a consistent check on the performance information given to customers. Those analysed represent a wide range of 'typical' performance estimate styles such as those based on calculators provided by manufacturers, those focused on RHI income and verbose estimates that (appear to) put stress on technical detail.

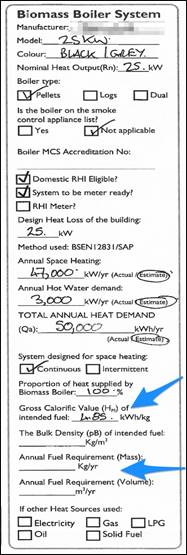

Compliance with the main MCS and RECC requirements is summarized in Table 4 below. Green indicates compliant practice; red indicates non-compliance and orange partial compliance. Compliance areas 15 and 16 were not assessed in most cases because the companies made incorrect assumptions about heat demand when calculating the RHI.

Table 4. Analysis of Heat Pump Performance Estimates.

The main findings of this analysis is summarised below.

- All three estimates that included 'alternative estimates' (using an alternative methodology) were presented in a non-compliant way. All three were very misleading.

- Seven out of the nine were not clear or accessible.

- One estimate gave no figure for overall heat demand. Two others gave information contradicted by values in alternative estimates with no explanation.

- Three out of the four estimates for GSHPs did not give the required technology-specific design information included in MIS 3005 – 4.4.24.

- The main performance values were consistent in only three estimates (for example, as is shown in Appendix E of MIS 3005).

- The main values were significantly misleading in five.

- None of the estimates gave all required key performance values:

- overall demand;

- renewable heat provided;

- electricity consumed by heat pump; and,

- combined SPF.

- Four of the seven estimates that gave RHI income predictions wrongly based the figures on their own demand assessment rather than the EPC.

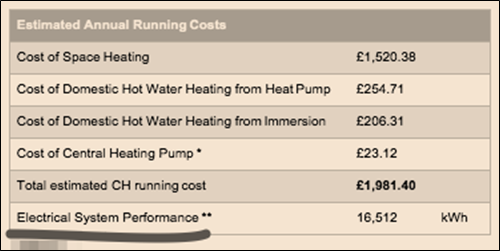

- The information about running costs was clear in five estimates, misleading in three and unclear in one.

The reasons why the calculations were assessed as misleading or incorrect are explained in 2.2.5.

It is worth highlighting here that the RECC requirement that estimates should be 'clear and accessible' is of critical importance. Estimates must carry the important values that enable customers to make an informed decision and the estimates must present the information in way customers can understand. Seven were not useful when measured against this benchmark. Estimates one, two, three, seven and eight carried very little information and certainly not enough to allow the customer to make a reasonable assessment of the proposal. Estimates five and six did include some useful information but almost all of this was not consistent with alternative estimates that were given greater prominence.

Estimates four and nine were reasonably compliant and contained useful information. These estimates were based on RECC or Easy MCS model documents which allow installers to input values into pre-formatted fields. Installers must fill in all necessary fields with the required information if these models are to be used in a fully compliant way.

2.2.4 Complaints

% of installations about which RECC received formal complaints (not including those registered with certification bodies unless joint):

ASHP – 2.68 in 2015 (>4,000 installs)

GSHP – 3.13 in 2015 (<900 installs)

These figures exclude:

- all technical complaints sent only to the certification bodies;

- all complaints directed only to the installers; and,

- all complaints where the customer has sought some other solution (such as legal action) without first involving RECC.

Relevant complaint case studies:

Claim of a miss-sold Air Source Heat Pump.

Installer informed complainant that he would receive RHI payments amounting to £620 quarterly. The actual RHI income being received is £160 quarterly and the shortfall over 7 years is clearly significant. The company has made two offers in return: a one-off payment of £1000 plus 5 years free servicing; or, a final offer of £1500 plus 2 years free servicing. The customer has rejected both offers. The dispute is on-going.

Inefficient Ground Source Heat Pump

This customer had a GSHP installed 3 years ago and claims the system has been inefficient and the electricity bills have been very high as a result. An independent engineer assessed the system and made technical recommendations for rectification implemented by the installer. The system is now working correctly but the consumer is seeking compensation for the 3 years of inefficiency and the cost of hiring the independent engineer. The dispute is on-going.

Very Inefficient Ground Source Heat Pump